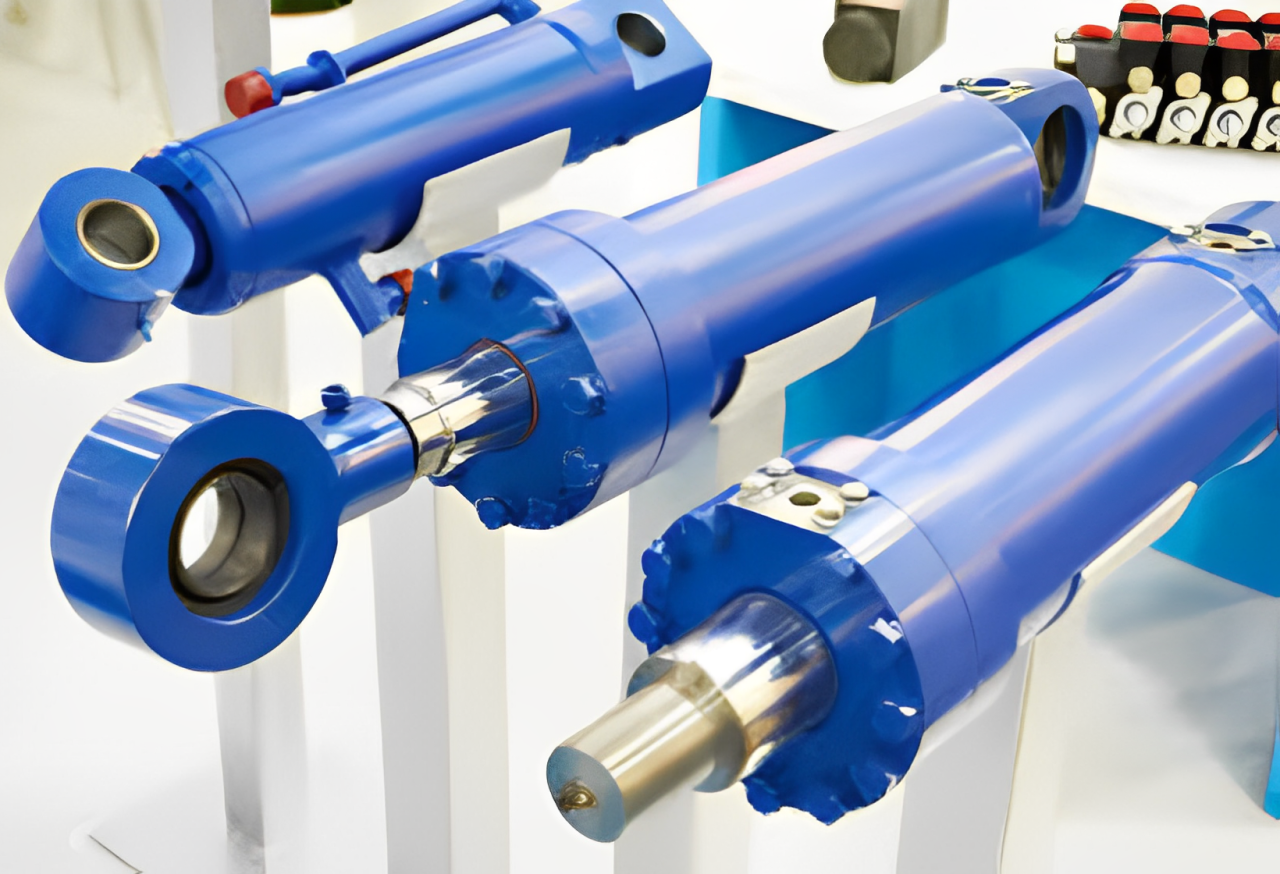

Essential for Power and Precision A hydraulic cylinder is a critical component in hydraulic systems, designed to create linear motion and force through hydraulic fluid pressure. Used widely in industries such as construction, manufacturing, and transportation, hydraulic cylinders enable heavy-duty equipment to perform tasks like lifting, pushing, and pulling with exceptional precision and power. How Hydraulic Cylinders Work Hydraulic cylinders operate based on Pascal’s Law, which states that pressure applied to a fluid within a confined space is transmitted equally in all directions. The cylinder consists of a barrel, a piston, and a piston rod. When hydraulic fluid is pumped into the cylinder, it moves the piston, converting fluid pressure into mechanical force, which then drives the movement of machinery.

Applications of Hydraulic Cylinders Hydraulic cylinders are essential components across many industries, providing controlled force and motion for various applications. In construction, they power heavy machinery like excavators, cranes, and bulldozers, enabling the lifting, digging, and pushing needed for demanding tasks. In agriculture, they enhance tractors, loaders, and harvesters, streamlining operations with reliable lifting and tilting capabilities. Manufacturing relies heavily on hydraulic cylinders for tasks like pressing, clamping, and cutting, where precision and high force are necessary. Industrial machinery such as injection molding machines and assembly lines depend on hydraulic cylinders for efficient, repetitive actions. In material handling, hydraulic cylinders in forklifts and conveyors make lifting and moving goods smoother and more efficient. For mining and drilling, hydraulic cylinders provide the power needed to operate equipment that extracts resources from challenging environments. They’re also essential in marine applications, powering steering, stabilizers, and hatch covers on ships to ensure safe operation in harsh conditions.